Quality

Quality

Quality Assurance

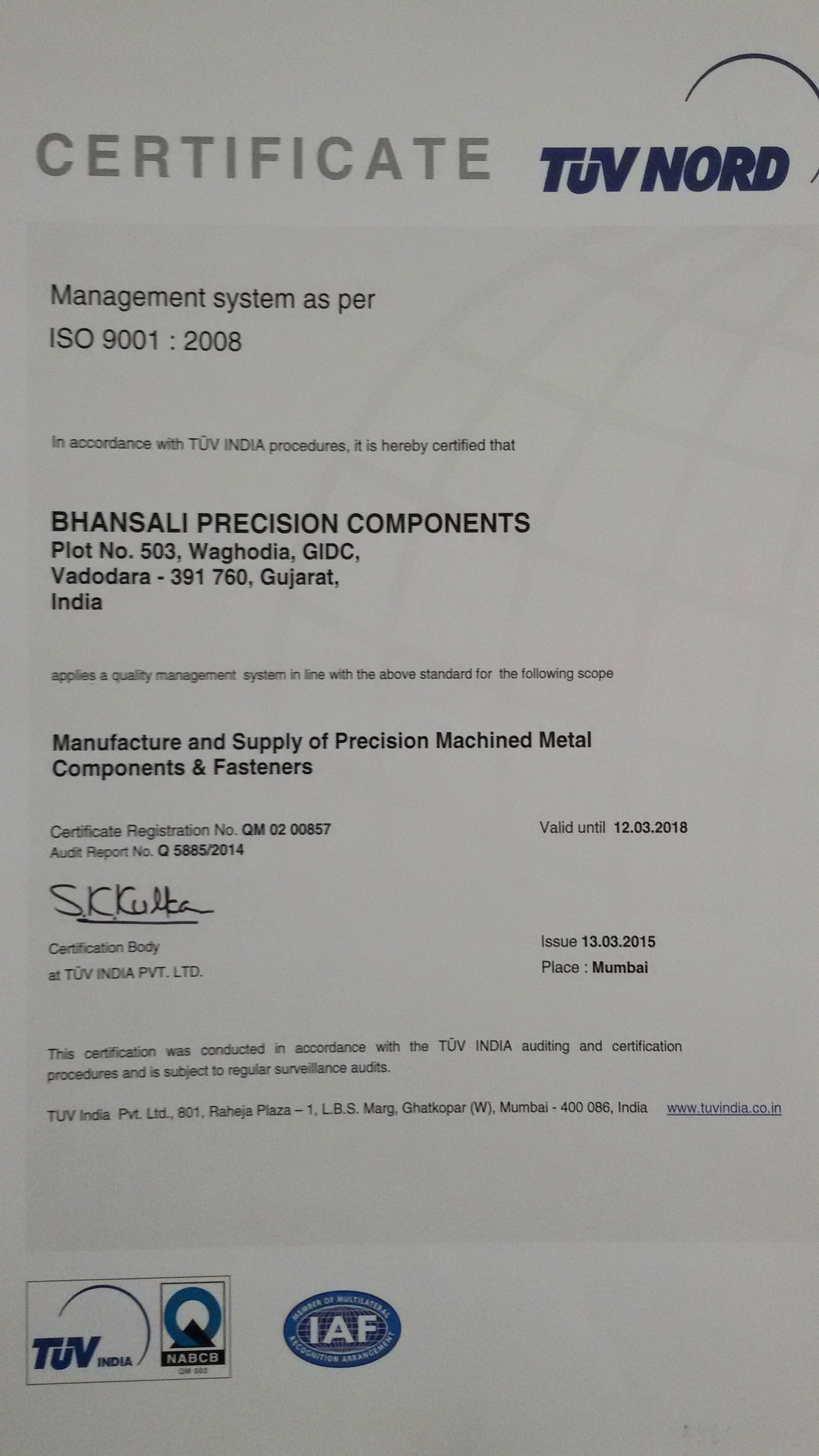

Quality Assurance at Bhansali starts with understanding the Customers Requirement and continues till the customer is completely satisfied with the delivery of products and services. Quality Control procedures are well defined and thoroughly implemented.

Incoming Inspection : Incoming Raw Materials are the foundation for the final product. We make sure that we start with the best raw materials. Our suppliers are well-informed with our quality requirements.

Raw Materials are inspected for:

- Dimensional properties such as tolerance, lobing, out-of-roundness, length, straightness

- Chemical & Mechanical Properties

- Surface Quality

In-process Materials are inspected for :

Dimensional properties such as tolerance, lobing, out-of-roundness, length, straightness

Surface Finish

Finished Goods Inspection : The quality assurance team in the finished goods department - we call them “Bhansali’s Internal Customer ”. They inspect materials from the customer ’s perspective. Our products comply with relative international standards such as ASTM, DIN, EN, BS, AMS, ASME, QQS, MIL, JIS, NACE and others. Test certifications comply with Euronorm EN 10204 3.1B /DIN 50049 3.1B.

Finished Goods are inspected as per customer specification for:

- Surface Finish

- Dimensional properties such as tolerance, lobing, out-of-roundness, length, straightness

- Final Mechanical Properties

- Packing,Color Coding,Marking